Metal fragmentation can be extensive and can slow down the process of metal-detector clearance dramatically. Generally the fragments result from human activity or are unintended battle-scrap. Many are on (or close to) the ground surface. To remove these, two magnetic handtools can be used. Both use powerful neodymium magnets to attract ferrous material and so reduce the number of signal-investigations that have to be made.

NOTE: In very moist ground conditions, the use of magnets may be inneffective and so omitted. In areas where active Type 72b mines are known to be concealed, the use of magnets on a handtool should be assessed in the Threat assessment for the site. Whatever the assessment, if active Type 72b mines are a known threat, hand-held magnets should never be used without first using a magnetic brush-rake over the area.

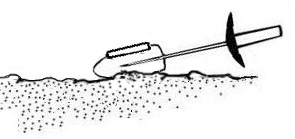

Magnet attached to trowel

Use of a magnet-trowel should be restricted if the Threat assessment at the Task indicates the possible presence of particularly sensitive devices.

A magnet-clip is attached to the blade of a trowel. The clip has magnets on both sides and is held to the trowel blade by the magnets being attracted to each other.

The trowel is passed over the ground above the signal indication.

Surface fragments are attracted to the magnet and can often be heard "clacking" onto it.

When the Threat assessment has not identified a hazard from especially sensitive devices, devices in an unstable condition, or active Type 72b mines, the trowel can be used to touch the ground lightly and to scrape raised soil on uneven ground.

When uneven ground is lightly scraped, the spoil is tipped over the magnet and off the trowel. Ferrous fragments stick to the magnet as they pass.

The trowel must not be used to dig down or apply downward pressure during the fragment-removal procedure.

After using the magnet-trowel, the area must be searched with the detector again as described in Section 3.3. This must be done whether or not fragments have been found because the action of the trowel may have moved the signals around. Not all metal is ferrous, and non-ferrous metal will not be attracted to the magnet.

Magnet attached to Brush-rake

When the Threat assessment has not identified a hazard from especially sensitive devices (or devices in an unstable condition) the Brush-rake magnet can be used to rake the area in which a metal-detector has signalled. This procedure can only be used AFTER the Brush rake has been tested.

Testing the Brush-rake involves using the rake to expose a rendered-safe test-mine in the ground conditions pertaining at the Task. The test-mine must be an example of the most sensitive anticipated threat in the Task area. The initiation mechanism must be intact and the High Explosive removed. The test-mine is concealed and a deminer wearing visor and frontal protection must attempt to expose the mine with the Brush-rake. If the Brush rake initiates the mechanism in the test-mine, the Brush-rake cannot be used where those threats are anticipated.

The Brush-rake (sometimes known as a leaf-rake) has a strip of neodymium magnets attached to its underside. The rake head is angled to the rake-handle so that the magnet-strip brushes the ground as the rake is used.

In a standing position, and holding the handle well back from the rake-head, the deminer rakes over the area where the metal-detector signaled.

The rake tines scratch the ground surface and can help to loosen fragments just below the ground surface, which are then attracted to the magnet strip.

After using the Brush-rake magnet, the area must be searched with the detector again. This must be done whether or not fragments have been found because the action of the rake may have moved the signals around. Not all metal is ferrous, and non-ferrous metal will not be attracted to the magnet.