| |

|

Type 72

Anti-personnel blast mine

|

|

|

The

Type 72 anti-personnel blast mine is a small plastic mine made

in China. It is known to have been used in Afghanistan, Angola,

Cambodia, China, Eritrea, Iraq, Kurdistan, Kuwait, Lebanon,

Mozambique, Namibia, Peru, Somalia, Sri Lanka, Sudan and Thailand.

The mine is green with a green rubber inset on the top. This

is a minimum-metal mine and can be very difficult to detect.

Height:

38mm

Diameter: 78mm

Main charge: 51g TNT

Type 72a separated

The

Type 72a is operated by applying pressure which causes a non-metallic

belville spring to 'click-through'. A metal pin in the centre of the belville spring strikes a small aluminium cased pyrotechnic, which fires the detonator that is beneath it inside an RDX booster. The booster detonates and its shock-wave initiates the 50g TNT main charge in the mine.

The metal content of a Type 72a is shown above. The white plastic ring is inside the top of the mine and is the sprung loaded arming-ring. The spring is a long, thin coil-spring which is very hard to detect with a metal-detector. The metal content of the mine is so low that it can be impossible to detect with many modern metal-detectors when the mine is in electromagnetic soil at a depths of 10-15cm.

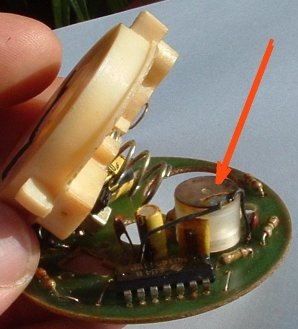

The Type 72b

incorporates

an electronic anti-tilt device that makes it relatively easy

to detect because of the presence of a circuit board and batteries.

Battery life is reported to be as short as 3 months after arming, but my research suggests that the two 1.5v batteries could last for ten years (although the entire circuit board is very vulnerable to moisture damage which would render the mine inactive far sooner).

The picture above shows the trembler anti-tilt device in the Type 72b. The trembler can be triggered by moving the mine through less than 10 degrees, so could be activated during excavation of a metal detector signal, and would almost certainly be activated if an exposed mine were picked up.

The Type 72b can only be initiated electronically. If the batteries are dead or the circuit broken, there is no inbuilt mechanical process to detonate the mine. (Poking at the pyrotechnic with a pin or a stick can still do it, of course.)

In my tests, the Type 72b's anti-tilt trembler device was reliably triggered by passing a strip of four neodymium magnets laterally above the mine at an 11mm distance. The magnets used were marketed as 1/2" x 1/4" x 1/8" thick, N40 Grade, Ni-Cu-Ni plated neodymium block magnets.

As a consequence (pending more detailed research results) using hand-held magnets in areas where active Type 72b mines are anticipated is not recommended UNLESS the magnets are attached to a blast resistant hand-tool that protects the user's hand by distance, ground angle and handguard (such as the AVS demining trowel or magnet wand). The relatively small amount of HE in the Type 72b (50g) means that such a tool used at a low angle to the ground should mean that blast injury to the hand is avoided (shock injury, sprains or broken bones may occur). Of course the user should also have suitable frontal PPE.

The

only easily visible difference between the Type 72a and the

Type 72b is in the shape of the arming pin. The 'a' has a round

ring on the pin. The 'b' has a triangular 'ring' on the pin.

Copies

of the Type 72a were made in South Africa and these are

reported to have been glued together, so may be impossible to

separate safely.

HOME

|

|